NIT Rourkela Scientists’ Biodegradable Film from Discarded Seeds: A Sustainable Packaging Revolution for a Greener Future

The global plastic crisis has reached unprecedented levels, choking our oceans, polluting our land, and permeating every aspect of our lives. Traditional plastics, designed for durability, persist for hundreds of years, creating an ecological burden that threatens biodiversity and human health. In the face of this escalating environmental catastrophe, the urgent demand for sustainable, eco-friendly alternatives to conventional packaging materials has become a paramount global priority.

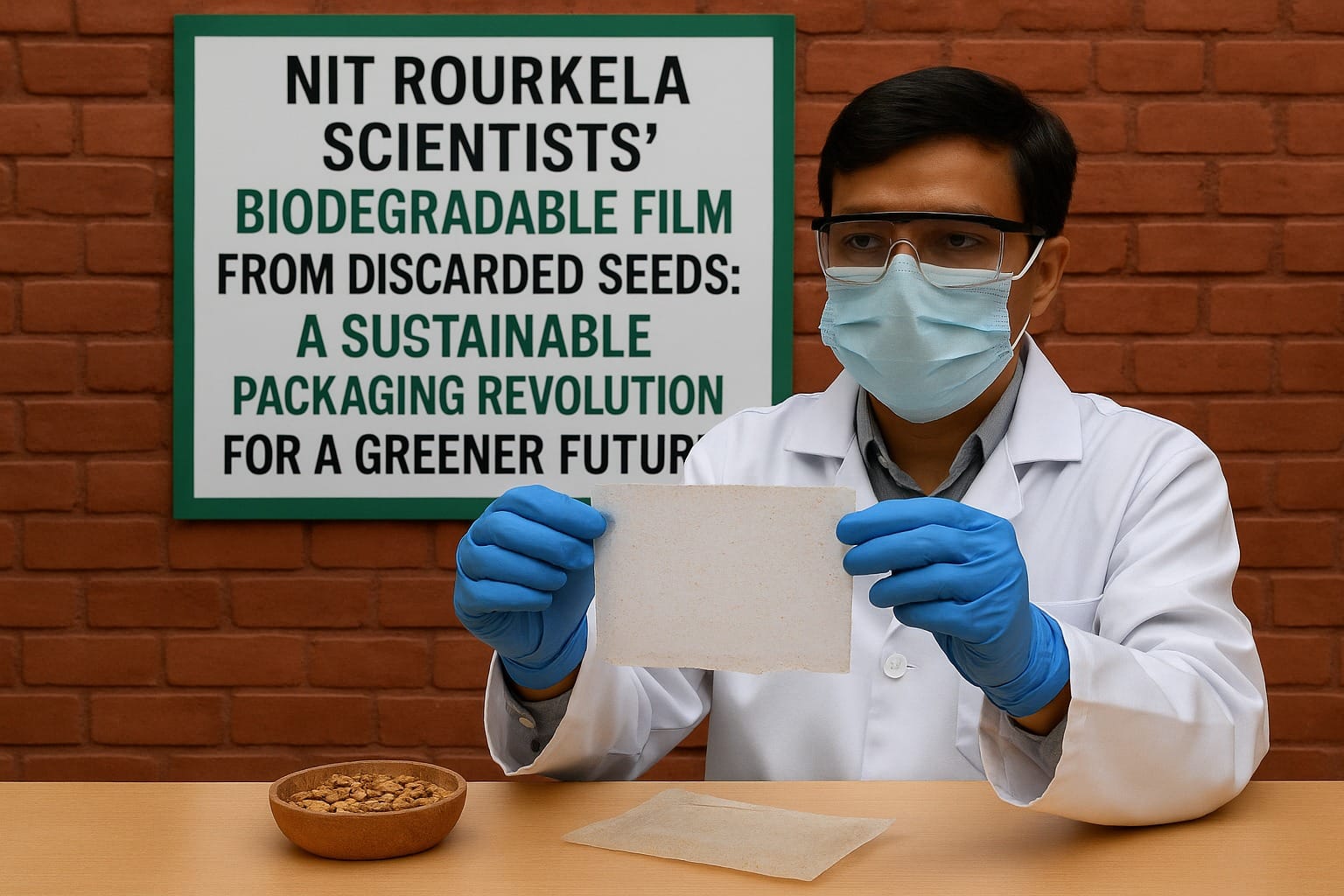

It is within this critical context that a groundbreaking innovation emerges from the heart of India: NIT Rourkela Scientists’ Biodegradable Film from Discarded Seeds: A Sustainable Packaging Revolution. This remarkable breakthrough, developed by researchers at the National Institute of Technology (NIT) Rourkela, offers a beacon of hope, transforming agricultural waste into a viable, biodegradable, and even edible film that promises to revolutionize the packaging industry and steer us towards a greener, more sustainable future.

This comprehensive exploration will delve into the harrowing scale of the plastic crisis, examine the existing landscape of sustainable alternatives, and then meticulously unpack the ingenious science behind NIT Rourkela’s pioneering innovation. We will explore the unique properties and multifaceted benefits of this biodegradable film, its diverse potential applications across various industries, and the inherent challenges that lie on the path to its widespread adoption. Finally, we will consider India’s crucial role in championing the global sustainability movement, driven by such visionary research and a commitment to a circular economy. Biodegradable Film

1. The Looming Plastic Crisis: A Global Environmental Catastrophe

The narrative of plastic, once hailed as a miracle material for its versatility and durability, has dramatically shifted to one of environmental villainy. Its very resilience, which made it so attractive, has become its greatest curse.

1.1. Scale of the Problem: An Overwhelming Tide

Globally, plastic production has skyrocketed, with billions of tons manufactured since the 1950s. A staggering proportion of this plastic is designed for single-use purposes, meaning it’s used for mere minutes before being discarded. Shockingly, only a tiny percentage – estimated to be less than 9% – of all plastic ever produced has been recycled. The vast majority accumulates in landfills, incinerators (releasing toxic fumes), or, most alarmingly, escapes into the natural environment. Biodegradable Film

1.2. Environmental Impact: Choking Ecosystems

The environmental footprint of plastic is devastating.

- Landfill Burden: Landfills are overflowing with plastic waste, which takes centuries to decompose, if at all, leaching harmful chemicals into the soil and groundwater.

- Ocean Pollution: An estimated 8 to 12 million tons of plastic enter our oceans annually. This plastic breaks down into smaller and smaller pieces called microplastics and nanoplastics, but never truly disappears. These particles are ubiquitous, found from the deepest ocean trenches to the Arctic ice.

- Harm to Wildlife: Marine animals, birds, and land animals often mistake plastic debris for food, leading to internal injuries, starvation, and entanglement. Microplastics are ingested by plankton and fish, entering the food chain.

- Ecosystem Disruption: Plastic pollution alters habitats, degrades soil quality, and can disrupt natural processes critical for ecosystem health. Coral reefs are particularly vulnerable, with plastic entanglement increasing disease susceptibility.

1.3. Health Implications: An Invisible Threat

The presence of microplastics in our environment has raised serious concerns about human health. These tiny particles have been found in drinking water, food (especially seafood), and even in the air we breathe. Research is ongoing, but initial studies suggest potential health risks, including inflammation, disruption of hormone systems, and even cellular damage, as plastics often contain harmful additives like phthalates and BPA. The sheer ubiquity of microplastics means we are constantly exposed, making the search for truly benign alternatives even more urgent. Biodegradable Film

1.4. Limitations of Current Solutions: A Complex Challenge

While recycling programs are widespread, they face significant limitations. Not all plastics are recyclable, and even those that are, can only be recycled a finite number of times before their quality degrades. Compostable plastics, while promising, often require specific industrial composting facilities to break down effectively, facilities that are not widely available globally.

Without proper infrastructure, these “compostable” materials can end up in landfills, where they behave much like conventional plastics due to lack of oxygen and microbial activity. The sheer volume of plastic produced continues to overwhelm existing waste management systems, highlighting the need for innovation at the material level itself. Biodegradable Film

2. The Quest for Sustainable Alternatives: Beyond Traditional Plastics

The recognition of plastic’s environmental toll has spurred intense research and development into sustainable alternatives. The goal is to find materials that offer similar functionality to conventional plastics but without the long-term environmental consequences.

2.1. Biodegradable vs. Compostable: A Crucial Distinction

It’s important to clarify the often-confused terms:

- Biodegradable: A material is biodegradable if it can be broken down by microorganisms (bacteria, fungi) into natural substances like water, carbon dioxide, and biomass. This process can happen over varying timeframes and in different environments (e.g., soil, water).

- Compostable: A subset of biodegradable materials, compostable materials break down into natural components within a specific timeframe (usually 90-180 days) and under specific conditions (e.g., high temperatures and controlled humidity in an industrial composting facility), leaving behind no toxic residue and creating nutrient-rich compost. Not all biodegradable materials are compostable under typical home composting conditions.

The true challenge lies in creating materials that are genuinely biodegradable in common environmental conditions, like a home compost bin or even naturally in soil or water, without leaving harmful residues.

2.2. Bioplastics – Current Landscape: Promise and Pitfalls

Bioplastics are derived from renewable biomass sources, such as corn starch, sugarcane, or cellulose. They offer a promising path away from fossil-fuel-based plastics.

- Starch-based plastics: Often made from corn, potato, or cassava starch. They are generally biodegradable. However, concerns exist about using food crops for plastic production, potentially competing with food security.

- Polylactic Acid (PLA): A common bioplastic derived from fermented plant starch (e.g., corn, sugarcane). PLA is compostable under industrial conditions but may not break down efficiently in home composts or landfills. It also has limitations in terms of heat resistance and barrier properties for certain applications.

- Polyhydroxyalkanoates (PHAs): Produced by microorganisms, PHAs are truly biodegradable in various natural environments, including soil and marine water. They show great promise but are currently more expensive to produce than PLA or conventional plastics.

- Cellulose-based plastics: Derived from wood pulp or other plant fibers. These can also be biodegradable and offer good strength.

2.3. Challenges: Cost, Scalability, and Specific Conditions

Despite the advancements, bioplastics face significant hurdles for widespread adoption:

- Cost: Many bioplastics are currently more expensive to produce than conventional petroleum-based plastics, making them less attractive to manufacturers and consumers.

- Scalability: Scaling up production from laboratory to industrial levels can be complex and capital-intensive.

- Specific Degradation Conditions: As mentioned, many “biodegradable” plastics require very specific conditions (like high heat and humidity in industrial composting facilities) to break down effectively. If these conditions aren’t met, they might end up as persistent pollutants, much like conventional plastics.

- Performance: Some bioplastics may not yet match the performance (e.g., shelf life, barrier properties, mechanical strength) of conventional plastics for all applications.

These challenges highlight the need for continuous innovation, particularly in finding abundant, low-cost, and truly environmentally friendly raw materials, and developing manufacturing processes that are both efficient and scalable. This is precisely where the innovation from NIT Rourkela shines.

3. NIT Rourkela Scientists: Innovators at the Forefront of Green Technology

Amidst the global scientific race for sustainable solutions, Indian institutions are increasingly making their mark. The National Institute of Technology (NIT) Rourkela stands out as a premier engineering and technological institute renowned for its strong focus on research and innovation, particularly in areas addressing contemporary global challenges.

3.1. Introduction to NIT Rourkela: A Hub of Research

NIT Rourkela, located in Odisha, has consistently been at the forefront of engineering education and research in India. Its faculty and students are engaged in diverse research projects aimed at solving real-world problems, with a growing emphasis on environmental sustainability, material science, and waste management.

The institute fosters an environment of interdisciplinary collaboration, allowing researchers from different departments to come together and develop holistic solutions. This innovative spirit is precisely what led to the groundbreaking development in biodegradable packaging.

3.2. The Research Team: Vision and Motivation

The innovation stems from the dedicated efforts of a research team led by Dr. Smita Mohanty, a prominent researcher at NIT Rourkela. Her team’s motivation was rooted in addressing two pressing environmental concerns simultaneously: the pervasive plastic pollution and the enormous volume of agricultural waste generated annually.

They sought a solution that not only offered a sustainable alternative to plastic but also created value from materials that would otherwise be discarded, thus embodying the principles of a circular economy. Their vision was to develop a material that was not only environmentally benign but also safe, effective, and potentially beneficial for human health if accidentally ingested, particularly in food packaging.

3.3. The Core Idea: Turning Waste into Value

The core brilliance of Dr. Mohanty’s team’s idea lies in its simplicity and sustainability: utilizing discarded seeds as the primary raw material for a biodegradable film. India, being an agrarian economy, generates vast quantities of agricultural waste, including fruit and vegetable seeds that are often thrown away after consumption or processing.

These “waste” products are rich in biopolymers, such as starch, cellulose, and proteins, which possess inherent properties suitable for material development. By tapping into this readily available and underutilized resource, the NIT Rourkela team aimed to provide a cost-effective, abundant, and truly renewable feedstock for bioplastic production, addressing the challenges of raw material sourcing that plague many other bioplastic ventures. This approach fundamentally shifts the paradigm from linear “take-make-dispose” to a circular “reduce-reuse-recycle-recover” model.

4. The Breakthrough Innovation: Biodegradable Film from Discarded Seeds

The NIT Rourkela team’s innovation involves a sophisticated process to convert humble fruit seeds, which are otherwise destined for landfills, into a high-performance biodegradable film. The core of this technology lies in leveraging the natural polymers present within these seeds.

4.1. The Source Material: Unlocking Nature’s Potential

The primary source materials identified and utilized by the scientists are the seeds of common fruits like Litchi and Mango. These fruits are consumed in enormous quantities across India, especially seasonally, leading to a massive accumulation of discarded seeds.

- Abundance: The sheer volume of mango and litchi seeds generated as waste makes them an incredibly abundant and low-cost raw material. This addresses a critical challenge for bioplastic production, which often struggles with the cost and availability of feedstock.

- Waste Valorization: By repurposing these discarded seeds, the innovation tackles the problem of agricultural waste management, transforming a liability into a valuable resource. This reduces landfill burden and associated environmental issues.

- Rich in Biopolymers: Mango and litchi seeds are naturally rich in starch, a complex carbohydrate polymer that can be extracted and modified to form a film. Starch, being a natural polymer, is inherently biodegradable. The seeds may also contain other beneficial compounds like cellulose or proteins, which can contribute to the film’s properties.

4.2. The Science Behind It: From Seed to Film

While the exact proprietary process involves detailed scientific steps, the general methodology likely involves:

- Extraction: The starch or other desired biopolymers are extracted from the dried and powdered seeds. This typically involves processes like grinding, washing, and chemical or enzymatic treatments to isolate the starch.

- Gelatinization/Modification: The extracted starch is then treated to alter its properties. This might involve heating in water (gelatinization) to form a viscous solution, and potentially incorporating plasticizers (like glycerol) to improve flexibility and prevent brittleness.

- Blending: The starch solution may be blended with other natural polymers or additives (e.g., cellulose derivatives, natural gums, or even antimicrobial agents) to enhance the film’s mechanical strength, barrier properties, or add functional benefits.

- Film Casting: The prepared solution is then cast onto a smooth surface (or passed through a die in an extrusion process) to form a thin film.

- Drying: The film is then carefully dried to remove moisture, resulting in a solid, flexible sheet.

4.3. Key Properties of the Film: Performance Meets Sustainability

The research team has engineered the film to possess a remarkable combination of properties, making it highly competitive with conventional plastics for various applications:

- Biodegradability: This is the core advantage. The film is designed to degrade rapidly and completely in natural environments, such as soil or water, within a relatively short period (the article indicates it degrades within a month). This means it won’t persist as pollution for centuries.

- Mechanical Strength & Flexibility: Despite being derived from natural materials, the film possesses sufficient mechanical strength and flexibility, making it durable enough for packaging applications without being brittle. It can withstand handling and provide structural integrity to packaged goods.

- Excellent Barrier Properties: Crucially for packaging, the film offers good barrier properties against oxygen and moisture. This is vital for protecting food items from spoilage, extending their shelf life, and preventing degradation from environmental factors.

- Transparency/Clarity: The film can be transparent, which is a desirable attribute for food packaging, allowing consumers to view the product inside.

- Edibility: A truly unique and revolutionary aspect of this film is its edible property. This means if the packaging accidentally gets into the food chain (e.g., ingested by animals) or even if humans consume small amounts, it poses no harm. This is a game-changer for reducing pollution risks.

- Non-toxic: Being derived from natural, food-grade sources and free from harmful petrochemicals, the film is inherently non-toxic and safe for direct food contact.

- Heat Resistance: The film exhibits good thermal stability, indicating it can withstand typical temperature variations during packaging, transport, and storage.

This combination of properties positions the NIT Rourkela innovation as a truly viable and superior alternative to conventional plastic films, especially in applications where biodegradability and safety are paramount.

5. Unpacking the Benefits: A Multi-Faceted Solution

The development of this biodegradable film from discarded seeds by NIT Rourkela scientists offers a cascade of benefits, addressing environmental, economic, and social dimensions of sustainability.

5.1. Environmental Impact: A Paradigm Shift

- Drastic Reduction in Plastic Waste: The most direct and significant benefit is the potential to drastically cut down on plastic waste generation. As the film naturally degrades, it eliminates the need for complex recycling processes and prevents accumulation in landfills and oceans.

- Lower Carbon Footprint: Producing bioplastics from agricultural waste often has a significantly lower carbon footprint compared to petrochemical-based plastics, as it relies on renewable resources and less energy-intensive processes.

- Reduced Pollution: The complete biodegradation of the film means no microplastic formation, no harmful chemical leaching, and a cleaner environment for ecosystems and human populations.

5.2. Waste Valorization: Transforming Trash into Treasure

- Circular Economy Model: This innovation perfectly embodies the principles of a circular economy by transforming what was once considered waste (discarded seeds) into a high-value product. This reduces waste, conserves resources, and creates a more sustainable production-consumption loop.

- Sustainable Resource Management: It offers a scalable solution for managing massive amounts of agricultural by-products, turning them into an economic asset rather than an environmental liability.

5.3. Economic Opportunity: Fuelling Green Growth

- New Industries and Job Creation: The large-scale production of this film could spur the creation of new processing units, manufacturing facilities, and related supply chains, generating employment opportunities in both rural (for waste collection and initial processing) and urban areas (for manufacturing and distribution).

- Local Value Creation: By using readily available local raw materials, it can empower local economies and reduce dependence on imported raw materials.

- Cost-Effectiveness: The low cost of discarded seeds as raw material offers the potential for the film to become cost-competitive with conventional plastics once scaled up, making it an economically attractive option for businesses.

5.4. Food Safety & Preservation: Beyond Packaging

- Edible and Non-toxic: The edible nature of the film is a revolutionary safety feature, especially for food packaging. It eliminates concerns about chemical leaching into food and poses no threat if accidentally ingested by humans or animals.

- Enhanced Shelf Life: The good barrier properties against oxygen and moisture mean better preservation of packaged food, reducing food waste – another significant environmental problem.

- Potential for Active Packaging: The film could potentially be infused with natural antimicrobial or antioxidant compounds from the seeds themselves or other sources, further enhancing food preservation capabilities.

5.5. Scalability Potential: India’s Advantage

Given India’s vast agricultural output, particularly in fruits like mangoes and litchis, the availability of raw material for this film is immense, making it highly scalable within the country. This positions India as a potential leader in developing and exporting such sustainable packaging solutions.

6. Applications and Potential Industries

The versatile properties of the biodegradable film from discarded seeds open up a vast array of potential applications across numerous industries, poised to replace conventional plastics where single-use and biodegradability are critical.

6.1. Food Packaging: The Most Obvious and Impactful Sector

- Fresh Produce: Wraps for fruits and vegetables (e.g., tomatoes, cucumbers), extending shelf life and replacing plastic cling films.

- Baked Goods: Packaging for bread, pastries, cookies, offering protection while ensuring biodegradability.

- Ready-to-Eat Meals/Snacks: Inner lining for containers, small sachets for condiments or dry snacks.

- Dairy Products: Inner layers or wraps for cheese, butter.

- Beverage Industry: Could potentially be developed into edible straws or even inner coatings for cups.

- Confectionery: Wrappers for candies and chocolates, eliminating persistent plastic waste from treats.

6.2. Single-Use Items: Tackling Everyday Waste

- Cutlery & Plates (if molded): While the innovation is a film, the raw material (seed starch) could potentially be adapted for molded products like disposable cutlery and plates that are truly compostable.

- Carry Bags: Thin, biodegradable carry bags for groceries or retail.

- Protective Wraps: For items that need a temporary protective layer.

6.3. Agriculture: Sustainable Farming Practices

- Mulch Films: Biodegradable films used in agriculture to suppress weeds, retain soil moisture, and regulate soil temperature. These films can be tilled directly into the soil after use, enriching it as they degrade.

- Seed Coatings: As an edible and non-toxic film, it could be used as a coating for seeds, potentially incorporating nutrients or protective agents, which then biodegrade harmlessly after germination.

6.4. Pharmaceutical Packaging: Safety and Sustainability

- Blister Packs: Potential for biodegradable blister packs for pills, offering a sustainable alternative to current plastic/foil combinations.

- Protective Wraps: For medical devices or sterile instruments.

6.5. Consumer Goods and Retail: A Broad Spectrum

- Textile Packaging: Inner wraps for clothing, hosiery.

- Cosmetics: Secondary packaging or wraps for cosmetic products.

- E-commerce Packaging: As a protective layer or void filler in shipping boxes, easily degradable after delivery.

- Stationery: Wraps for notebooks, pens.

The edible property of the film makes it particularly attractive for applications where accidental ingestion or contamination is a concern, positioning it as a truly safe and sustainable choice across diverse sectors.

7. Challenges and The Road Ahead

While NIT Rourkela’s biodegradable film represents a significant leap forward, its journey from laboratory innovation to widespread market adoption will face several challenges that need strategic navigation.

7.1. Scaling Production: From Lab to Industrial Scale

- Technology Transfer: Converting a successful laboratory process into a large-scale industrial manufacturing operation requires substantial investment in infrastructure, machinery, and expertise.

- Process Optimization: Fine-tuning the production process for efficiency, consistency, and cost-effectiveness at commercial volumes. This includes optimizing raw material sourcing, extraction, and film formation.

- Quality Control: Ensuring uniform quality, thickness, and performance of the film across large batches.

7.2. Cost-Effectiveness: Competing with Established Plastics

- Economy of Scale: Initial production costs for novel materials are often higher. Achieving economies of scale will be crucial to bring the price down to compete with conventional plastics, which benefit from decades of optimized mass production.

- Raw Material Processing Cost: While discarded seeds are cheap, the cost of processing them to extract the necessary polymers can be significant. Efficient and low-energy extraction methods will be key.

7.3. Market Adoption: Shifting Mindsets and Supply Chains

- Consumer Education: Educating consumers about the benefits and proper disposal of biodegradable films (e.g., distinguishing them from non-biodegradable “greenwashing” products).

- Industry Buy-in: Convincing large corporations and packaging manufacturers to switch from established plastic supply chains to new biodegradable alternatives, which may require changes in machinery and processes.

- Performance Expectations: Meeting the varied and stringent performance demands of different industries (e.g., specific barrier properties, tensile strength, printability).

7.4. Policy Support: Government’s Crucial Role

- Incentives for Bioplastics: Government incentives (tax breaks, subsidies) for research, production, and adoption of genuinely biodegradable materials can accelerate market growth.

- Regulations and Bans: Stricter regulations on single-use plastics and outright bans (like India’s ongoing efforts) create market demand for alternatives and push industries towards sustainable solutions.

- Standardization: Developing clear standards and certifications for biodegradable and compostable products to prevent misleading claims and build consumer trust.

7.5. Further R&D: Continuous Improvement

- Enhancing Properties: Ongoing research to improve the film’s barrier properties, strength, shelf life, and versatility for a wider range of applications.

- Exploring Other Waste Sources: Investigating other abundant agricultural wastes (e.g., other fruit peels, vegetable scraps, crop residues) as potential raw materials.

- Active Packaging: Researching ways to incorporate active compounds (e.g., natural antimicrobials, antioxidants) directly into the film to further enhance food preservation.

7.6. Patenting and Commercialization: Protecting the Innovation

Securing robust intellectual property rights (patents) for the technology is crucial to protect the innovation and attract investment for commercialization. Partnerships with industry players and startups will be vital for bringing the film from the lab to the market at scale.

8. India’s Role in the Global Sustainability Movement

India, with its vast agricultural sector, burgeoning scientific community, and pressing environmental challenges, is uniquely positioned to play a leading role in the global sustainability movement. The NIT Rourkela innovation is a prime example of this potential.

8.1. Plastic Ban Initiatives: Driving Domestic Demand

The Indian government has shown increasing commitment to combating plastic pollution, with nationwide bans on single-use plastics being implemented in phases. These policies create a massive domestic market demand for sustainable alternatives, providing a strong incentive for local innovation and production.

8.2. Startup Ecosystem: Fostering Green Tech

India’s vibrant startup ecosystem is increasingly focusing on green technologies, renewable energy, and sustainable materials. Innovations like the biodegradable film from NIT Rourkela can attract significant venture capital and entrepreneurial talent, accelerating their journey to market.

8.3. Agricultural Waste Potential: A National Advantage

As one of the world’s largest agricultural producers, India generates an enormous amount of biomass waste annually. This waste, if properly managed and valorized, represents a virtually inexhaustible and renewable source of raw materials for bioplastics, biofuels, and other bio-based products. This gives India a significant competitive advantage in the bio-economy.

8.4. Circular Economy Model: Leading by Example

The NIT Rourkela innovation perfectly aligns with the principles of a circular economy – designing out waste and pollution, keeping products and materials in use, and regenerating natural systems. By developing such closed-loop solutions, India can set an example for other developing nations and contribute significantly to global sustainability goals. This shift from a linear “take-make-dispose” economy to a circular one is essential for long-term environmental health and resource security.

Conclusion: A Beacon of Hope for a Plastic-Free Future

The NIT Rourkela Scientists’ Biodegradable Film from Discarded Seeds: A Sustainable Packaging Revolution stands as a powerful testament to human ingenuity and the boundless potential of nature to provide solutions to our most pressing challenges. By transforming discarded fruit seeds into a high-performance, truly biodegradable, and even edible packaging film, this innovation offers a tangible pathway towards a future less dependent on harmful conventional plastics.

This breakthrough not only addresses the urgent environmental crisis of plastic pollution but also opens doors for waste valorization, economic opportunities, and enhanced food safety. While challenges related to scaling, cost-effectiveness, and market adoption remain, the foundational research provides a robust platform for further development and commercialization. India’s commitment to sustainable development, coupled with its rich agricultural resources and growing scientific prowess, positions it as a key player in driving this crucial transition. The discarded seed, once considered mere waste, now embodies the promise of a cleaner, greener, and more sustainable world, inspiring hope for a truly plastic-free future.

🌐 The Power of Our District PR Ecosystem

We are not just a media agency—we are building an entire district-level digital infrastructure with:

Each site provides:

- SEO blog space

- Video PR hosting

- Local business features

- Event coverage

- News updates

Biodegradable Film, Biodegradable Film, Biodegradable Film, Biodegradable Film , Biodegradable Film , Biodegradable Film , Biodegradable Film , Biodegradable Film , Biodegradable Film , Biodegradable Film , Biodegradable Film , Biodegradable Film Biodegradable Film , Biodegradable Film Biodegradable Film , Biodegradable Film , Biodegradable Film , Biodegradable Film , Biodegradable Film , Biodegradable Film , Biodegradable Film Biodegradable Film Biodegradable Film

- NIT Rourkela Scientists’ Biodegradable Film from Discarded Seeds: A Sustainable Packaging Revolution for a Greener Future

- 1. The Looming Plastic Crisis: A Global Environmental Catastrophe

- 2. The Quest for Sustainable Alternatives: Beyond Traditional Plastics

- 3. NIT Rourkela Scientists: Innovators at the Forefront of Green Technology

- 4. The Breakthrough Innovation: Biodegradable Film from Discarded Seeds

- 5. Unpacking the Benefits: A Multi-Faceted Solution

- 6. Applications and Potential Industries

- 7. Challenges and The Road Ahead

- 7.1. Scaling Production: From Lab to Industrial Scale

- 7.2. Cost-Effectiveness: Competing with Established Plastics

- 7.3. Market Adoption: Shifting Mindsets and Supply Chains

- 7.4. Policy Support: Government’s Crucial Role

- 7.5. Further R&D: Continuous Improvement

- 7.6. Patenting and Commercialization: Protecting the Innovation

- 8. India’s Role in the Global Sustainability Movement

- Conclusion: A Beacon of Hope for a Plastic-Free Future

- 🌐 The Power of Our District PR Ecosystem